see all jobs

Foster + Partners ramp up research into metal-based 3D printing

The architecture studio of Norman Foster are actively seeking to develop a large-scale hybrid machine that can produce metal building components directly from CAD models using 3D printing.

Foster + Partners are collaborating with ten companies and research institutes to explore the potential of metal-based 3D printing using additive and subtractive manufacturing processes that will enable production within a short timeframe.

The proposed technology, called the Large Additive Subtractive Integrated Modular Machine (LASIMM), would also produce components for the aerospace, energy and transport sectors.

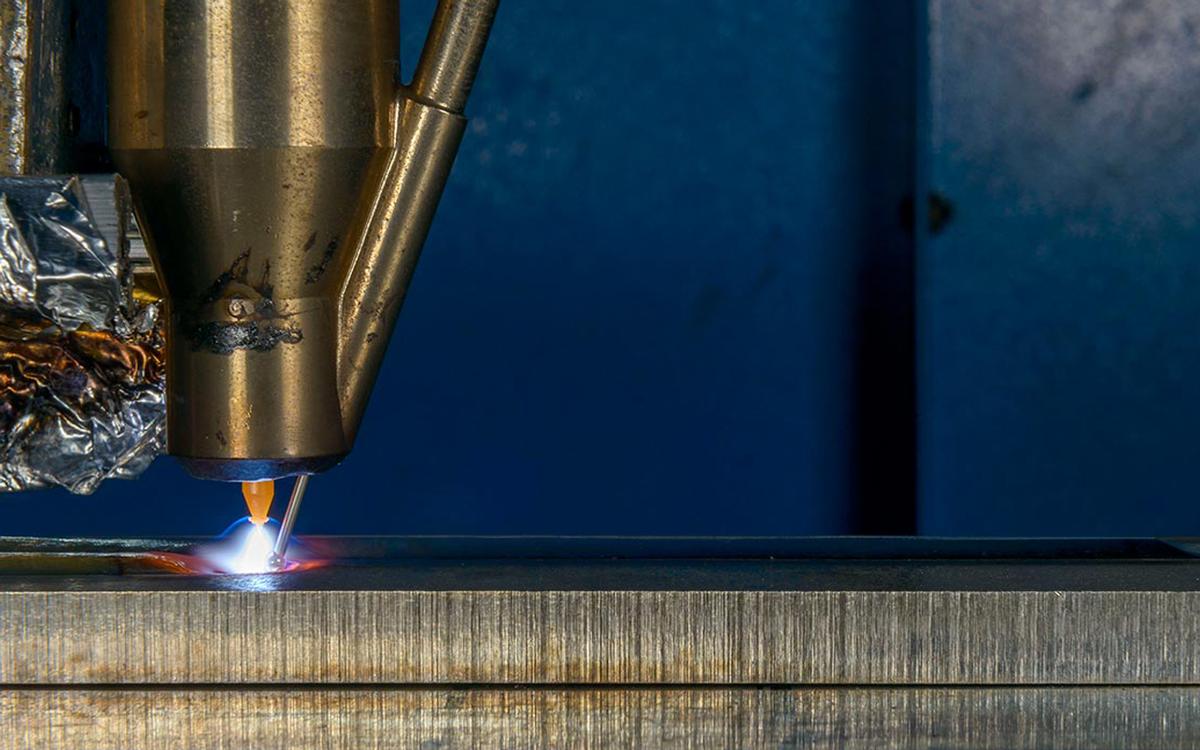

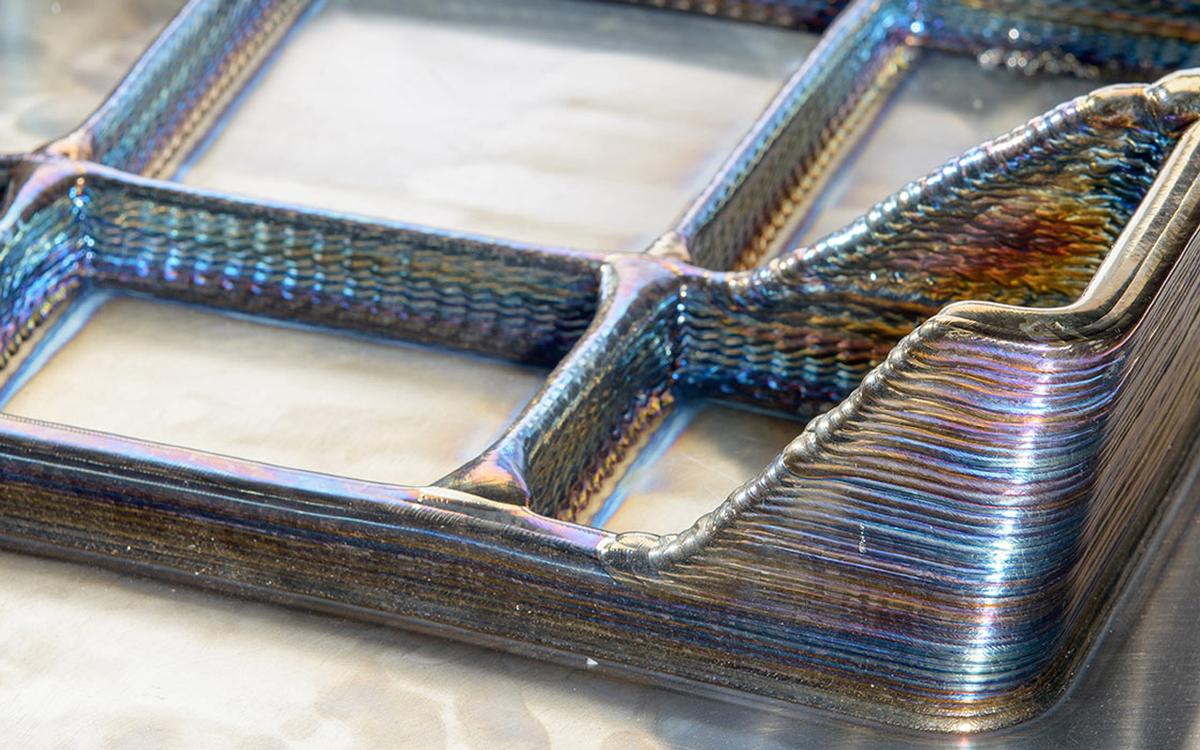

It would feature a modular configuration of industrial robot arms and a specialised milling robot – “the first for rapid arc weld deposition of aluminium, steel, and titanium into a near-net shape, and the second for machining away surplus material to provide the final finish.”

“3D printing technology has revolutionised the architectural and engineering industry over the past few decades with rapid prototyping playing an increasingly pivotal role in the design process,” said the studio in a statement.

“This process now also offers myriad possibilities in the construction of prefabricated building components, enabling entire buildings to be 3D printed in the future.

“The LASIMM would enable the building industry to move away from standardised components and towards bespoke solutions for every building. It would also mean that these components could be produced within a reduced timeframe at a fraction of the cost.”

Foster + Partners were an early adopter of 3D printing and rapid prototyping technology, and the firm purchased their first 3D printer in 2004. They have also been involved with Loughborough University and other partners in bringing large-scale 3D concrete printing technology to market.

The LASIMM project is currently in the first year of a three-year programme. Foster + Partners are providing end user feedback based on the requirements of the building industry.

Soon, to demonstrate the suitability of the technology, LASIMM will create a number of components that have been proposed by industrial partners. Research into the machine has been partly funded by the European Union’s Horizon 2020 research and innovation programme.

The consortium developing the concept is formed of the following partners, including the entire supply chain needed to produce such a machine, two universities and two research institutes:

• The European Federation for Welding, Joining and Cutting

• BAE Systems (Operations)

• Foster + Partners

• Vestas Wind Systems

• Cranfield University

• Global Robots

• Loxin2002

• Helmholtz-Zentrum

• Geesthacht Zentrum fur Material – und Kustenforschung GMBH

• Delcam

• Instituto Superior Técnico

More News

- News by sector (all)

- All news

- Fitness

- Personal trainer

- Sport

- Spa

- Swimming

- Hospitality

- Entertainment & Gaming

- Commercial Leisure

- Property

- Architecture

- Design

- Tourism

- Travel

- Attractions

- Theme & Water Parks

- Arts & Culture

- Heritage & Museums

- Parks & Countryside

- Sales & Marketing

- Public Sector

- Training

- People

- Executive

- Apprenticeships

- Suppliers