see all jobs

How can you 3D print an entire functioning building? MIT group claims to have found the answer

Researchers from the Massachusetts Institute of Technology (MIT) have announced a new breakthrough in the architectural applications of 3D printing, with the design of a system that can produce the basic structure of an entire building.

MIT’s Mediated Matter Group – which focuses on “nature-inspired design and design-inspired nature” – claim the machine they have invented will eventually produce buildings faster and less expensively than traditional construction methods allow.

What’s more, a structure could be completely customised to the needs of a particular site and the desires of its maker, with different materials and material densities incorporated as the process goes along to provide optimum combinations of strength and insulation.

The system, which the researchers call a Digital Construction Platform (DCP), consists of a tracked vehicle that carries a large, industrial robotic arm, which has a smaller, precision-motion robotic arm at its end. This can be used to direct any conventional or unconventional construction nozzle, such as those used for pouring concrete or spraying insulation material, as well as additional digital fabrication end effectors.

Unlike typical 3D printing systems, most of which use some kind of an enclosed, fixed structure to support their nozzles and are limited to building objects that can fit within their overall enclosure, this free-moving system can construct an object of any size.

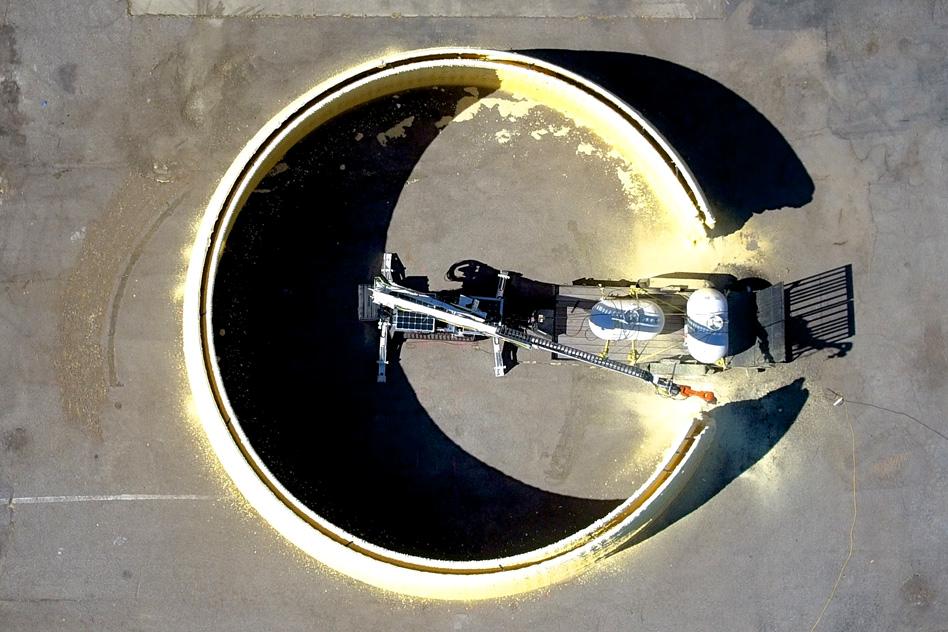

To prove the concept, the researchers used a prototype to build the basic structure of the walls of a 50ft diameter, 12ft high dome. The structure was completed in less than 14 hours of printing time.

The system fabricated the foam-insulation framework used to form a finished concrete structure – similar to traditional commercial techniques. It was able to create complex shapes and overhangs, including a wide, built-in bench..

The research was inspired by the fact that 3D printing has grown to include not just plastics, but also metal, glass, and even food, and that a machine that can offer material flexibility can have a huge impact on the design and construction industries.

The Mediated Matter group’s overall vision is for a machine that can, in a single system, create structure and skin and beams and windows in a single production process, adapting multiple design and construction processes as it is being built. Even wiring and plumbing can be inserted into the mold before the concrete is poured, providing a finished wall structure all at once.

Built-in sensors for temperature, light, and other parameters would allow the machine to make adjustments to the structure as it is built.

This adaptability means a building produced in a matter of hours and days “could have thicker, more insulated walls on its north side in cold climates, or walls that taper from bottom to top as their load-bearing requirements decrease, or curves that help the structure withstand winds.”

“The construction industry is still mostly doing things the way it has for hundreds of years,” said system development leader Steven Keating. “Those buildings are rectilinear, mostly built from single materials, put together with saws and nails. But what if every building could be individualised and designed using on-site environmental data?

“With this new process, we can replace one of the key parts of making a building, right now. It could be integrated into a building site tomorrow.”

Keating added that the whole system could be operated electrically, even powered by solar panels. The idea is that it could be deployed to remote regions, or to areas for disaster relief after a major storm or earthquake, to provide durable shelter rapidly.

“The ultimate vision is in the future, to have something totally autonomous, that you could send to the moon or Mars or Antarctica, and it would just go out and make these buildings for years,” he said. “We also wanted to show that we could build something tomorrow that could be used right away.”

The robotic system is described in detail in the journal Science Robotics. Keating has worked with Julian Leland and Levi Cai, both research assistants in the Mediated Matter grou, and Neri Oxman, group director and an MIT associate professor.

She said: “The ability to design and digitally fabricate multifunctional structures in a single build embodies a shift from the machine age to the biological age – from considering the building as a machine to live in, made of standardised parts, to the building as an organism, which is computationally grown, additively manufactured, and possibly biologically augmented.

“So to me it’s not merely a printer, but an entirely new way of thinking about making, that facilitates a paradigm shift in the area of digital fabrication, but also for architectural design.

“Our system points to a future vision of digital construction that enables new possibilities on our planet and beyond.”

More News

- News by sector (all)

- All news

- Fitness

- Personal trainer

- Sport

- Spa

- Swimming

- Hospitality

- Entertainment & Gaming

- Commercial Leisure

- Property

- Architecture

- Design

- Tourism

- Travel

- Attractions

- Theme & Water Parks

- Arts & Culture

- Heritage & Museums

- Parks & Countryside

- Sales & Marketing

- Public Sector

- Training

- People

- Executive

- Apprenticeships

- Suppliers